Turbine maps are required for modeling gas turbine systems accurately. The efficiency at part-load affects the thermal efficiency (and thus specific fuel consumption) of the gas turbine directly, the variation of the corrected flow with pressure ratio affects at low power the exhaust gas temperature significantly. At the 2022 ISABE conference in Ottawa, Canada, I presented a paper which uses turbine maps generated with TurPer:

Conceptual Gas Turbine Design: The Role of Turbine Maps

Joachim Kurzke

ISABE-2022-151

The true maps are seldom available outside industry and therefore it is common practice to scale maps from similar machines. Alternatively one can calculate maps, provided the component geometry is known at least approximately. Turbine power requirement, mass flow, a rough idea about the dimensions of the turbine flow annulus as well as spool speed can be found from conceptional engine design studies as they are feasible with GasTurb, for example.

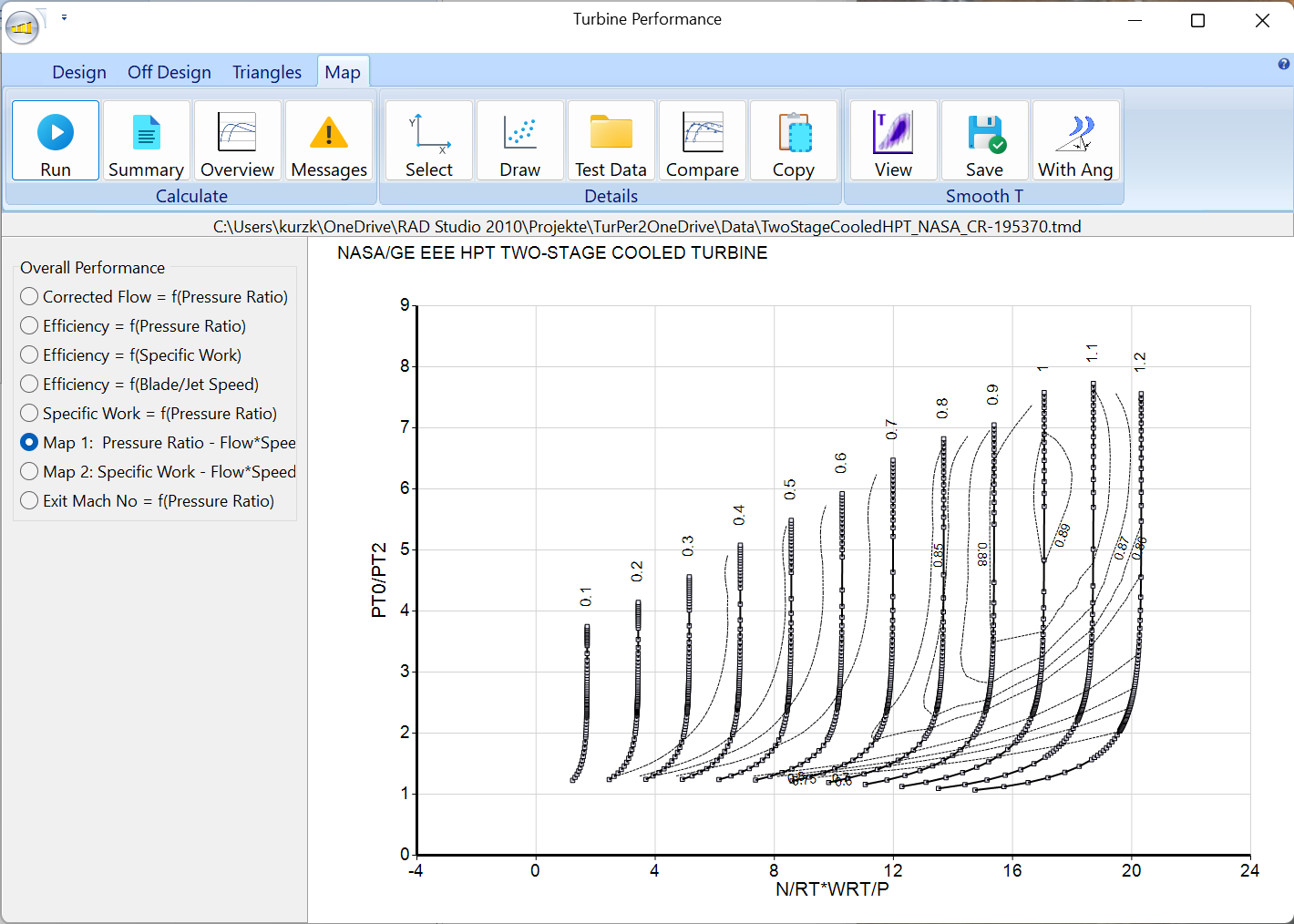

TurPer (stands for Turbine Performance) is a derivative of the FORTRAN code published in 1967 by E. E. Flagg from the GENERAL ELECTRIC COMPANY (NASA CR-710). This code has been improved over time, and in 1994 Arthur J. Glassman from the University of Toledo, Ohio, published (NASA CR-195370) "Modeling Improvements and Users Manual for Axial-Flow Turbine Off-Design Computer Code AXOD". TurPer generates input files for the program Smooth T which in turn produces tables suitable for gas turbine performance programs.

The number of input data required for running TurPer is significantly less than needed for the original Flagg program or its derivative AXOD. The comparison with measurements from turbine rigs shows - regardless of the simplifications - that maps calculated with TurPer are as accurate as those calculated with AXOD. The output of TurPer consists of various tables with different degree of detail, a set of pre-defined graphics, velocity diagrams and an option to compose figures with arbitrary content from the numbers available.

My future plans are to implement a turbine design option which uses input data created with GasTurb or similar conceptual design programs. Turbine cooling and its effect on efficiency will be considered in more detail. The option to design counter rotating turbines and calculating their off-design performance are on the wish list of later TurPer versions.

GasTurb is a trademark of GasTurb GmbH, Aachen, Germany